Storm Board types available

![]()

Storm Board HI (High Impact)

Made from 100% waste materials

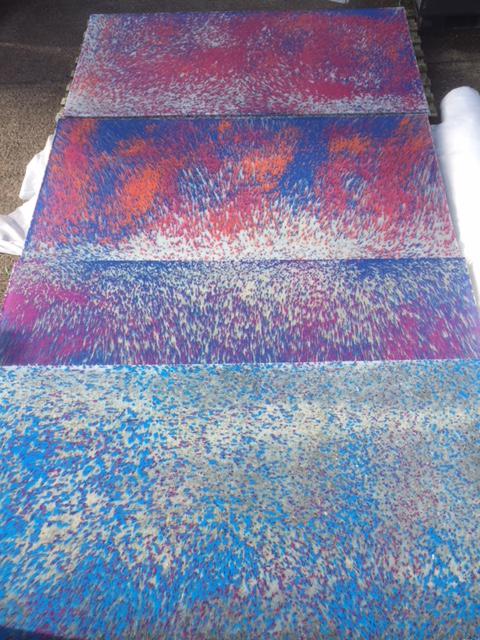

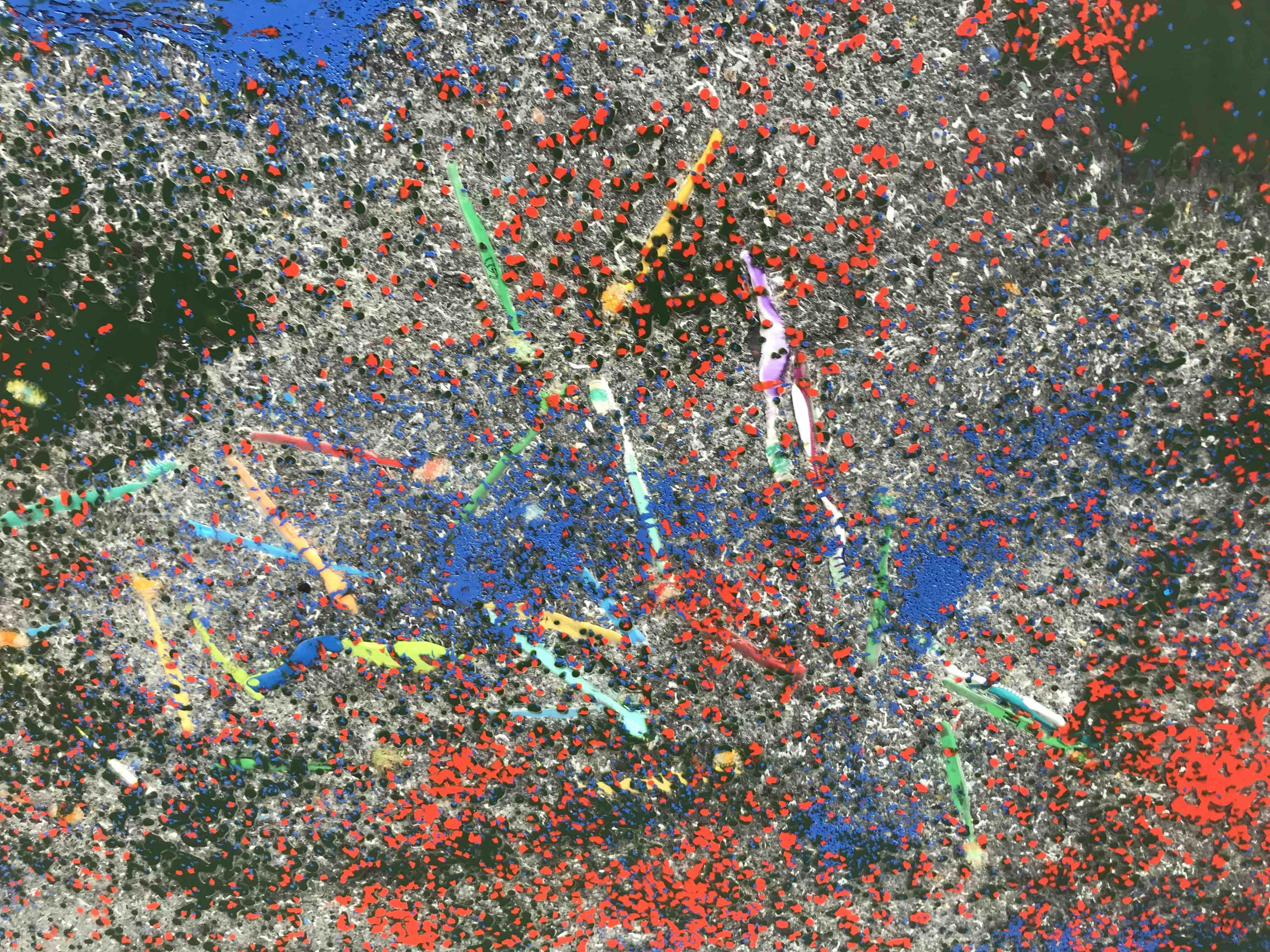

This tough general purpose board out performs its wooden contempories in outdoor and wet environments. The standard colour is speckled grey/black or speckled green. With a Polyolefin skin, it is easy to clean, graffiti resistant and weather proof. There is a new range of Splash board, which show off the wild recycled colours, being recycled the exact colour combination cannot be guaranteed. Other colours are available with orders over 200 boards.

Applications: site hoardings, washrooms, cubicles, shower pods, tanking, outdoor furniture, climbing walls, raised beds, compost bins, animal welfare, stables, sheds, flood protection, staff canteens and site office furniture.

.jpeg)

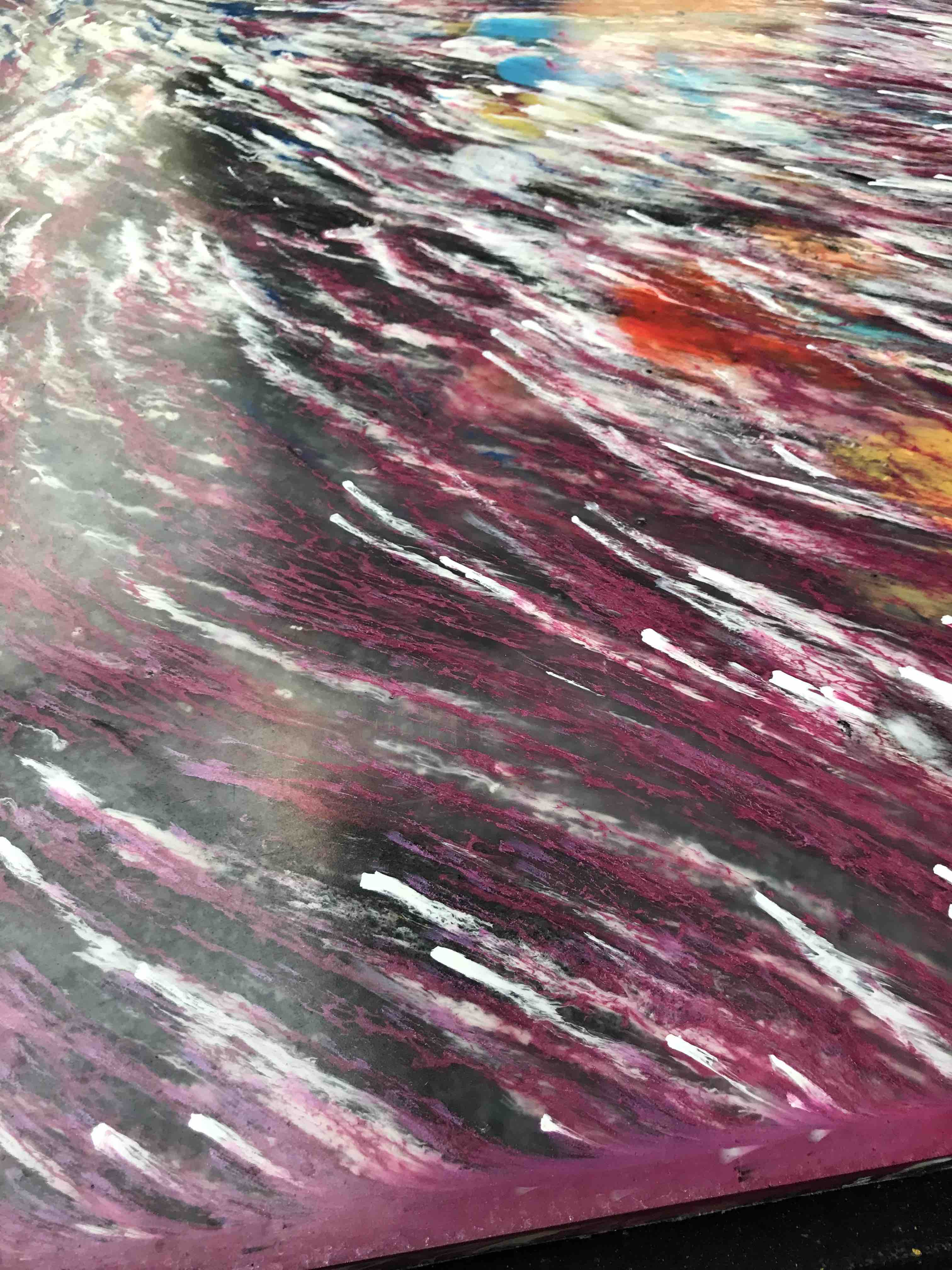

Speckled Green & Black.

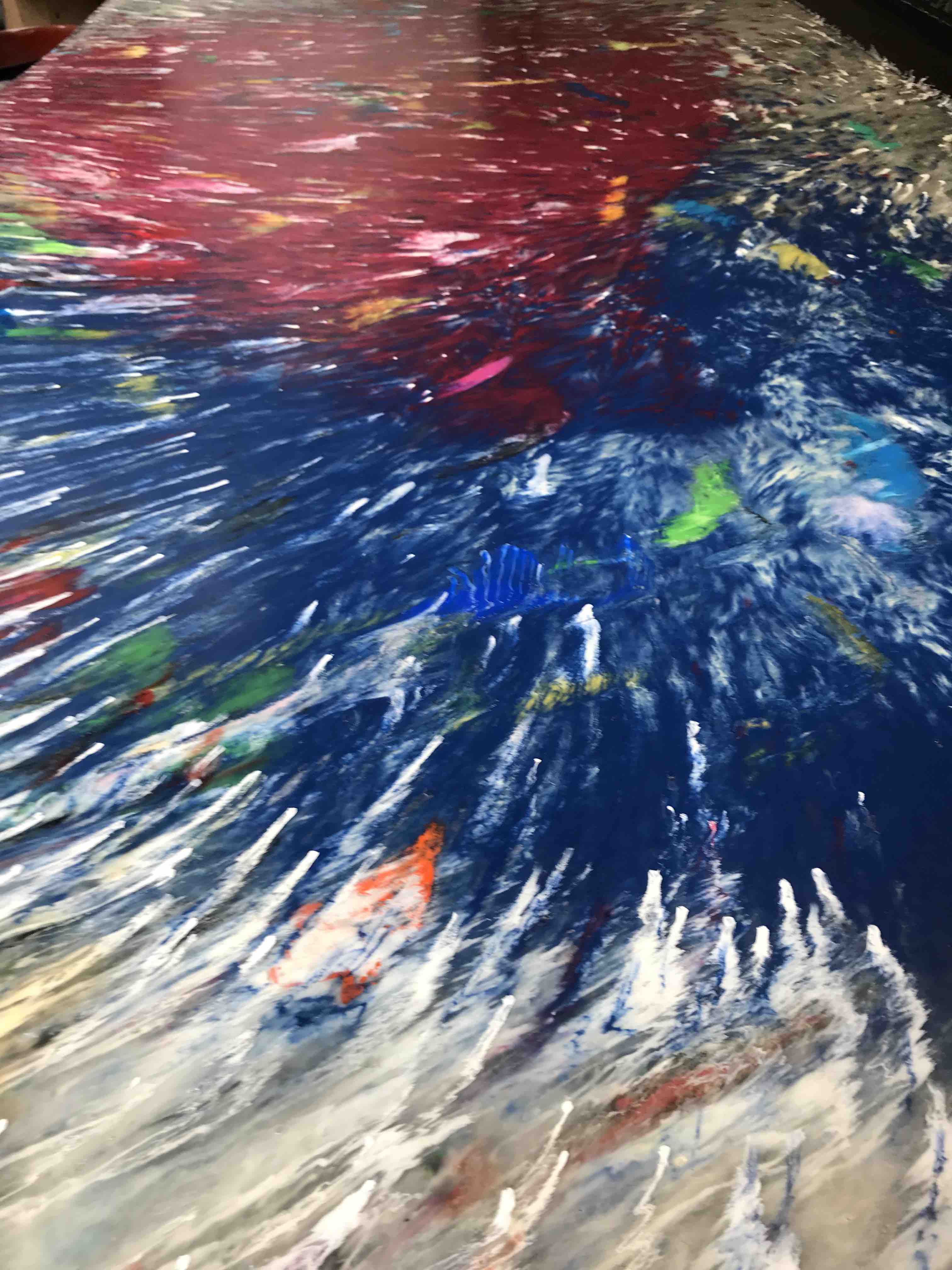

Splash boards

Storm Board HI with integral fire retardant skin

Made from 70% waste materials

This board is made with a fire retardant polyolefin skin, and standard mixed waste polymer core. The skin material grade is V0 in accordance with UL94, and is UKAS certified. The standard colour is black, other colours are available with orders over 200 boards.

Storm Board SF (Shop Fitting)

Storm Board SF was developed to be a sustainable alternative for the shop fitting industry. Storm Board SF has a lower coefficient of expansion and does not expand/contract as a result of heat as much as Storm Board HI, thus giving more reliable tolerances for CNC machining. Storm Board SF is very stiff, and does not have the high impact strength of Storm Board HI. Standard delivery colour is black flecked.

Storm Board SF can be CNC machined and printed directly. It is not as UV stable as Storm Board HI, and would require cork coating if used for extended periods outside. Storm Board SF maintains its water resistant qualities.

Applications: Ideal for furniture, shop fitting and construction.

Which board to choose?

HI is your tough, non stick, UV resistant weather proof board. It can be plastic welded to seal edges and create tanks with a Leister welder manual: Welwyn Tool/ Leister

Automatic version: Leister Automatic

HI is resistant to solvents and graffiti, so they are easy to clean, but difficult to paint. If you need to paint it then sand it down to create a key and use plastic automotive paint, you can get some great effects.

HI does expand and contract more than wood, so needs expansion gaps. This also makes the board formable, and bendable, in case you want to go around corners…

Standard vinyl graphic film will stick to the HI board.

SF is a much stiffer board, making it more brittle, with more accurate tolerances. Ideal for indoor shop fitting and furniture, outdoors it needs a coating. It is easier to paint and laminate than HI board. Using “wraps” is and ideal way to create the surface look you want: william smith range

Coatings and Laminates

Self adhesive or laminate coatings bond better to SF board. For hoardings and outdoor signage, where HI board is used then a vinyl graphic can be applied

You can have "wood look, " and even a fire retardant laminate, if fact there are loads of coatings from leather look to brushed metal or even slate. As our boards are made from plastic they are ideal for outdoor use: william smith exterior

we can even do grafitti style logos...

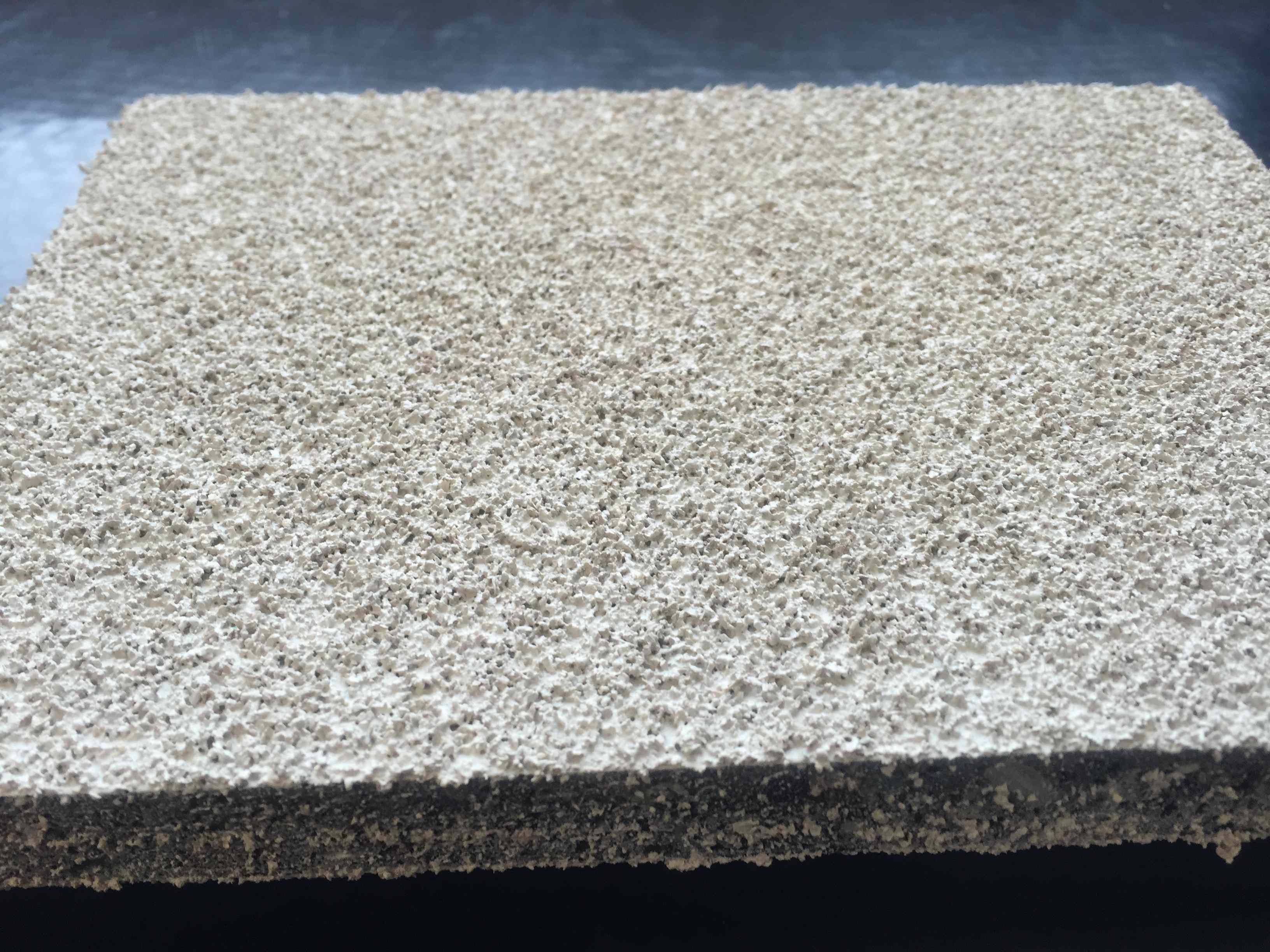

For a rendered look with great acoustic properties we recommend Corksol, which is a recycled cork coating.

They can provide sustainable Cork and Quartz coatings for the boards, which enhance the performance and “look” of the boards: Fire rating – Euro Class B, Acoustic properties, no on site plastering/plaster board/decorating, easy to clean and maintain, non-slip properties.

Expansion/ Contraction

Plastic will expand/ contract more than wood. Over a 2.4m length Storm Board HI will expand approx. 3mm/10C in the heat, whereas plywood and Storm Board SF only 1.5mm, (plywood the opposite way in the heat and the cold). So it does require a bit of thought and patience when using Storm Board for the first time. Using a “top hat” or clamp system will allow the boards to expand and contract, as well as speeding up the assembly/ disassembly of the system. There is less mechanical damage using a top hat system. If using screw fittings, then screw through the board to the timber using penny washers, and don’t force the fixing too tightly.

Warping/ Oversize format

When the boards arrive they won’t be completely flat. Storm Board is a plastic moulded product made from mixed waste and will never be as flat as a sanded ply, it can appear to have a dip on the pallet, but once hung straightens out. It is produced “oversize” so that it can be cut down to 8ft x 4 4ft, as not all plastics react the same way. However after 6 months in the wet, plywood tolerances go out the window and Storm Board will look the same after years outdoors.

Plywood is flat on day one, not on day 100. Storm Board will move, and last a lot longer outdoors. Use the right system, and this is not an issue.